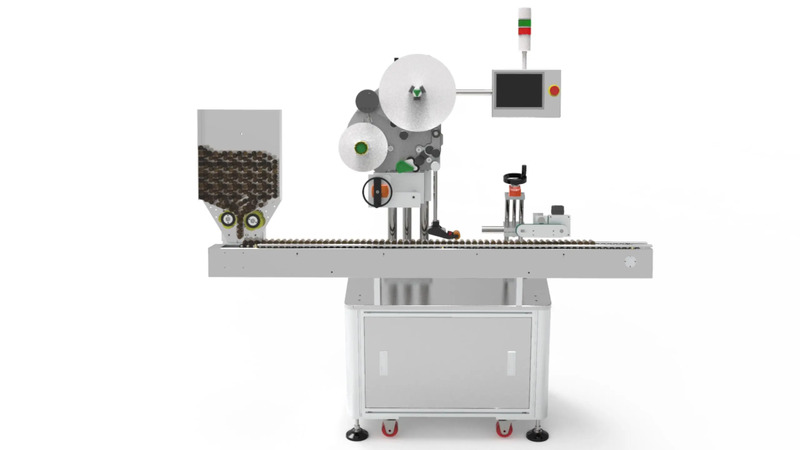

Automatic Rolling Labelling Machine

Labelling machine plays an important role in pharmaceutical industries to provide detail of product by sticking label on product container by considering this KTS provides Automatic Rolling Labelling machine, suitable for Sticker Labelling on Ampoule, PFS, Thin and long products in pharmaceutical as well as Beverages, Cosmetics etc type of industries. Specially this type of machine is used for Full/Partial labelling on different size of product. This automatic model is equipped with Star wheel, roller conveyor and wrapping device resulting in a simple operation of wrapping of label on product.

Salient Features

- Machine is designed and manufactured in accordance with cGMP compliance.

- Structure is made of SS 304.

- Roller Conveyor System as per product.

- Conveyor system equipped with imported AC frequency variable drive for variable speed with constant torque.

- Star wheel system to feed product on roller conveyor for labelling operation.

- Machine suitable for round products like Ampoule, PFS, Thin and long products.

- Full / Partial labelling is possible.

- Specially designed label dispenser unit for Label Release.

- Specially designed wrapping unit for smooth and accurate half/full labelling.

- Reel mounting (Size: 300 mm) to hang the roll with core ID of 76mm.

- Break assembly to avoid variation during releasing of roll.

- Various label position adjustment with the help of adjustment assembly.

- Most reliable components of pneumatics and electrical/electronic such as AC motor, AC Drive, PLC & HMI, Sensor, MCB & relay “CE” make.

Optional Features

- NO product NO label.

- Fiber optic based Label Gap sensor to sense the gap between two labels. (Sensor Make: LEUZE/BANNER/SICK).

- Fiber Optic based Product sensor to sense the product (Sensor Make: LEUZE/BANNER/SICK).

- Unit is made compact design & user friendly operating HMI.

- Over Current / Temperature Protection.

- Special HMI function like Product Delay & Pre dispensing Length that makes easy machine setting.

- Label dispensing speed can set digitally by using HMI.

- System Refresh: This function is used to feed the label size into the Controller. Whenever you change to a new label type, or size press REF key. Three labels are dispensed to get the exact label size.

- Motor unlock facility for changing the label roll.

- Total counter facility is available with password protected reset button.

- PPM (Product per machine) facility is available.

- Touchscreen HMI for total operation.

- Capacity to speed control AC drive from HMI.

- Multiple program facility.

- Label Break/Roll End/Missing Label (02 Nos.) - Machine Stop. When there are two consecutive missing labels or a broken label role this error occurs. The HMI screen shows it as “Label Break/Roll End/Missing Label”.

- Two nos. continuous missing label in the label role automatic machine stop.

- The Panel unit is made in compact design & easy serviceable/Removable.

- Label roll end alarm indication with tower light & sound alarm (Add on price for sensor set/tower light). (Optional Feature)

- Batch printing facility is available (Add on price). (Optional Feature)

Technical Specifications

| Model | SLKTS-A-RL |

|---|---|

| Model Type | Servo/Stepper |

| Product Shape | Round |

| Product Material | Glass/PET/HDPE |

| Product Type | Ampoule, PFS, Thin and long products |

| Output (Product/hour) max. | 2500 to 3000 (Depends on Label and product diameter) |

| Label height (mm) | 10 to 200 |

| Label Length (mm) | 12 to 285 |

| Gap between Two Label (mm) min. | 5 to 6 |

| Label Roll Dia. (mm) max. | 300 |

| Label Core Dia. (mm) | 75 |

| Power consumption (hp) | 3 |

| Power supply | Single Phase, 230 Volts, 50 Hz |

*Rights of technical improvements & modification reserved.

Are You Interested in KTS Pharmatech Machine?