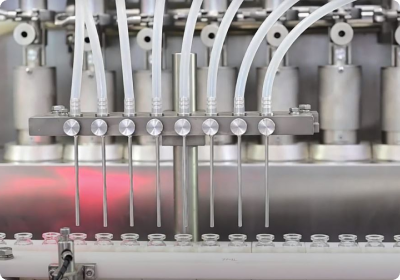

Automatic Ampoule Filling and Sealing Machine

Automatic Ampoule Filling and Sealing machine model has built to fulfil the requirement in pharmaceutical Filling Industry. Ampoules are filled with liquid then purged with nitrogen gas and finally sealed using combustible gases. Machine is having specially designed filling pump for precise filling of liquid with neck centring during filling operation. Ampoule are sealed immediately after filling the liquid in order to avoid contamination. Machine made from high quality stainless steel 316L materials as per cGMP requirements.

Machine having flexibility to fill seal ampoules of 1 ml to 25 ml capacity. Operating on the volumetric piston pumps type filling principle, the device can fill 10 to 250 ampoule per minute.

The required gases for sealing or filling the ampoules are oxygen and LPG (Propane). This KTS range of Filler sealer is perfect for all kinds of open mouth glass ampoules.

Salient Features

- Machine is designed and manufactured in accordance with cGMP compliance.

- Free from cross contamination.

- SS 304 wire mesh Infeed conveyor.

- Capacity of filling volume from 1ml to 30ml with the help of Syringe Pump.

- Filling accuracy: +- 0.5 to +- 1 %.

- Inbuilt hot gas suction system.

- Ease of filling system validation for Large/medium/small batch production.

- Pre and Post gassing system.

- All contacting parts made of SS 316L.

- Servo based PLC control with Touch Screen HMI.

- Variable frequency drive for speed control.

- “No Ampoule – No filling” System.

- “No Ampoule – Machine stop” System.

- PLC with GUI (Optional).

- Tray Collection at Outfeed.

Technical Specifications

| Model | FILLKTS-AL-AFS120 | FILLKTS-AL-AFS300 |

|---|---|---|

| Product Type | Open Mouth Glass Ampoules | |

| Product Diameter (mm) | 10.75 to 22.50 | |

| Product Height (mm) | 60 to 113 | |

| Filling volume Range (ml) | 1 to 20 | |

| Filling Precision | +-1 % | |

| No. of Filling Head | 8 | 12 |

| Output (Product/hour) max. @ 1 ml fill vol. | 14400 | 18000 |

| Power Consumption (hp) | 1 | 2 |

| Power Supply | Three Phase / 440 V AC / 50 Hz | |

*Rights of technical improvements & modification reserved.