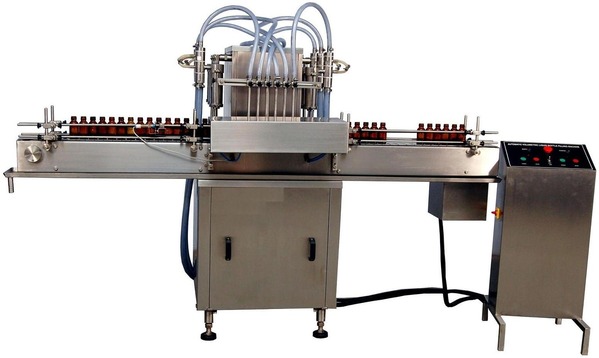

Automatic Volumetric Liquid Filling Machine

Automatic volumetric liquid filling machine is working on principle of volumetric Filling with diving nozzle. This economic, compact and versatile model is generally used for filling various viscosity liquid into container. Machine consists of Welded base structure enclosed with Stainless Steel Doors, Product transmission conveyor, Filling Nozzles, Pneumatic/Mechanical product stopper system, Syringe. Empty containers will move on conveyor from infeed side and stop below filling Nozzle with the help of stoppering system. Filling nozzles automatically enter the neck of the container at a pre-set depth and after filling, return to its original position. The dosing block with a hexagonal bolt fitted below syringes from where operator can adjust filling volume.

Salient Features

- Machine is designed and manufactured in accordance with cGMP compliance.

- Welded Base structure covered with SS Door.

- All contacting parts made of SS 316 material.

- Use of food grade PVC braided pipe for flow of liquid.

- Conveyor system with self-lubricating UHMW-PE bottom guide for slat chain and adjustable side guides.

- Drip tray under the conveyor.

- Elegant and easy control panel for total control on operation.

- ±1% Filling accuracy in single dose.

Optional Features

- Automatic chain washing system for conveyor belt.

- Inbuilt pre-inspection.

- Safety Acrylic Cabinet with SS Pipe Frame structure.

- Nitrogen Flushing.

- Holding tank with/without stirrer.

Technical Specifications

| Model | FILLKTS-AL-VC2 | FILLKTS-AL-VC4 | FILLKTS-AL-VC6 | FILLKTS-AL-VC8 |

|---|---|---|---|---|

| Product Type | Plastic / Glass / HDPE bottles, Tin and Container etc. | |||

| Product Diameter (mm) | 30 to 100 | |||

| Filling volume Range (ml) | 10 to 1000 | |||

| No. of Filling Syringe | 2 | 4 | 6 | 8 |

| Output (Product/hour) max. | 60 | 80 | 120 | 160 |

| Filling Precision | +-1 % depending of liquid with single Dose | |||

| Power Consumption (hp) | 2 | |||

| Power Supply | Three Phase, 440 Volts, 50 Hz | |||

| Change over parts requirement: | ||||

| Syringe, Nozzle, Hose Pipe for inlet and outlet | ||||

*Rights of technical improvements & modification reserved.