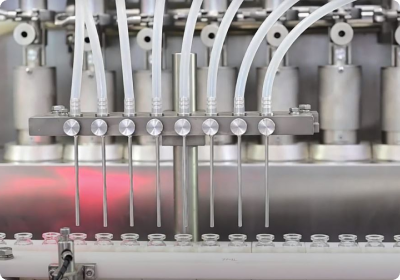

Semi-Automatic Volumetric Liquid Filling Machine

Semi-Automatic volumetric liquid filling machine is working on principle of volumetric Filling. This economic, compact and versatile model is generally used in small/medium industry. Machine consists of Welded base structure enclosed with Stainless Steel Doors, reciprocating Filling Nozzles, Product Holder, Syringe, Pedal Switch. Containers have to place below the filling nozzle manually in Product holder. Filling nozzles automatically enter the neck of the container at a pre-set depth and after filling, return to its original position. The dosing block with a hexagonal bolt fitted below syringes from where operator can adjust filling volume.

Salient Features

- Design and manufactured under accordance with GMP standard.

- All Contact parts made from SS 316 and Non contacted parts are made from engineering plastic, SS 304 and other FDA approved materials.

- Welded Base structure covered with SS Door.

- Semi-automatic with filling range from 5 ml to 1000 ml.

- ± 1 % Filling accuracy in single dose.

- Use of food grade PVC braided pipe for flow of liquid.

- Minimum change overtime, from one size to another bottle or fill size.

Technical Specifications

| Model | FILLKTS-SAL-VC2 |

|---|---|

| Product Type | Plastic / Glass / HDPE bottles, Tin and Container |

| Fill Size (ml) | 5 to 1000 (with the help of Change over) |

| Output (Product/hour) max. | 900-1200 |

| No. of Syringe | 2 |

| Power Consumption (hp) | 0.5 |

| Power Supply | Single Phase, 230 Volts, 50 Hz |

*Rights of technical improvements & modification reserved.

Are You Interested in KTS Pharmatech Machine?