Edible Oil Packing Line

KTS Pharmatech is a leading manufacturer of advanced packing line machines for edible oils. Their systems are designed to efficiently handle the complete packaging process for a variety of edible oils, including vegetable, olive, and specialty oils.

KTS Pharmatech’s edible oil packing line machines are engineered to deliver reliable performance, improve operational efficiency, and meet the rigorous demands of the food industry.

Key Features of KTS Pharmatech’s Edible Oil Packing Line Machines:

- Precise Filling: Advanced filling technology ensures accurate and consistent measurement of edible oils, minimizing waste and maximizing efficiency.

- Sealing Mechanism: High-quality sealing systems secure the containers, preserving freshness and preventing leakage.

- Labelling: Integrated labelling units apply labels with precision, providing clear product information and compliance with industry regulations.

- Automation: Streamlined automation processes enhance throughput and reduce the need for manual intervention, improving overall productivity.

- Flexibility: Capable of handling various container sizes and types, accommodating the diverse packaging needs of edible oils.

Applications:

- Food and Beverage Industry: Ideal for packaging edible oils for retail and bulk distribution, ensuring high standards of quality and safety.

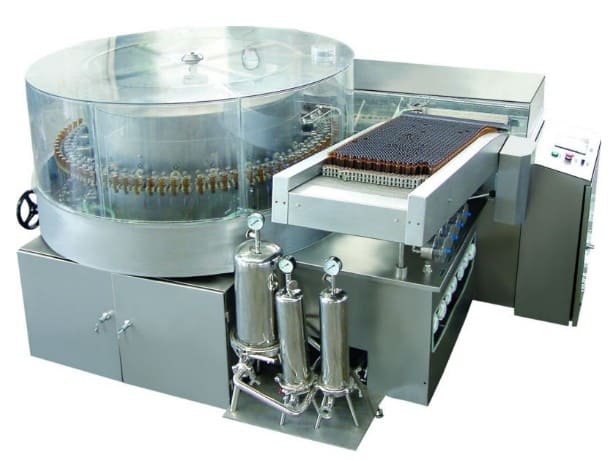

Rotary Turn Table

One of the earliest designs for accumulation or unscrambling is the Rotary Turn table. KTS Provide The rotary design Accumulation turn table that can handle multiple container sizes and materials. Standard (non-custom) diameters are 24”, 28”, 30”, 36″ and 48″. Top discs are stainless steel Coated with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers.

Liquid Filling machine

KTS Pharmatech offers a range of oral liquid filling machines tailored to meet diverse production needs:

- Volumetric Fillers: Provide precise liquid measurement with piston or peristaltic mechanisms, suitable for varying viscosities.

- Gravity Fillers: Utilize gravity for efficient filling of low-viscosity liquids.

- Pump Fillers: Feature gear or diaphragm pumps for accurate filling of both thin and thick liquids.

- Overflow Fillers: Ensure uniform fill levels by managing excess liquid.

- Automatic Systems: Integrate with capping and labeling for high-speed, automated filling processes.

- Multi-Head Fillers: Increase efficiency and throughput with multiple filling heads for large-scale production.

These categories ensure KTS Pharmatech can offer solutions that enhance precision, efficiency, and reliability in oral liquid production.

Capping machine

KTS Pharmatech’s Screw and ROPP (Roll-On Pilfer Proof) Capping Machines are engineered to provide reliable and efficient closure solutions for a wide range of packaging needs.

- Screw Capping Machines: Designed for precision and versatility, these machines apply screw caps to bottles with consistent torque and secure closure. Ideal for various industries, including pharmaceuticals, food, and beverages, they ensure tamper-evident and leak-proof seals.

- ROPP Capping Machines: Utilize a roll-on technique to apply aluminum caps, creating a tamper-evident seal that protects product integrity. Perfect for applications where security and authenticity are crucial, such as in the pharmaceutical and cosmetic industries.

Both types of capping machines are built to enhance productivity, reduce manual handling, and maintain high-quality standards. With advanced technology and user-friendly controls, KTS Pharmatech’s capping solutions ensure reliable performance and compliance with industry regulations.

Bottle labelling machine

KTS Pharmatech provides a Vial labelling machine is designed to efficiently and accurately apply labels to ampoules, small sealed vials commonly used in the pharmaceutical industry. These machines operate at high speeds to handle large production volumes, ensuring precise and consistent label placement. They are versatile, accommodating various Vial sizes and label types, and feature user-friendly controls for easy operation. Vial labelling machines are essential for maintaining compliance and traceability in pharmaceutical manufacturing.