Injectable Dry Powder Vial Packing Line

KTS Pharmatech offers an advanced injectable dry powder vial packing line solution, specifically designed to handle the complex and delicate process of filling, sealing, and packaging dry powder medications. This solution is ideal for pharmaceutical companies focused on producing sterile and precisely dosed injectable powder formulations.

KTS Pharmatech’s injectable dry powder vial packing line solution is a reliable, efficient, and customizable option for pharmaceutical manufacturers aiming to produce high-quality injectable powder medications with precision and adherence to industry regulations.

Key Components:

- Vial Washing Machine: Thoroughly cleans and sterilizes vials, preparing them for the aseptic filling process by removing particulate and microbial contaminants.

- Sterilization and Depyrogenation Tunnel: Heats vials to eliminate pyrogens and dries them in a controlled environment, ensuring they are sterile and ready for powder filling.

- Powder Filling Machine: Accurately doses and fills vials with the specified amount of dry powder using vacuum or auger-based filling systems, ensuring precision and consistency.

- Rubber Stoppering Machine: Automatically inserts rubber stoppers into the filled vials to maintain sterility and protect the powder from contamination.

- Capping Machine: Applies aluminum caps to the stoppered vials, securely sealing them to preserve the integrity of the contents.

- Inspection System: Conducts a thorough inspection of vials to detect and reject any with filling errors, defects, or sealing issues, ensuring only high-quality products proceed.

- Labeling Machine: Attaches labels to the vials, providing essential information such as drug name, dosage, batch number, and expiration date.

- Cartoning Machine: Packs the labeled vials into cartons, preparing them for distribution and ensuring they are protected during transportation.

Benefits:

- High Precision and Accuracy: KTS Pharmatech’s powder filling technology ensures exact dosing, critical for maintaining the efficacy and safety of injectable drugs.

- Sterile Processing: The entire line is designed to operate in a sterile environment, minimizing the risk of contamination and ensuring compliance with cGMP standards.

- Integrated Automation: The packing line is fully automated, reducing the need for manual intervention and increasing production efficiency while maintaining high-quality standards.

- Customizable for Different Needs: The solution can be customized to accommodate various vial sizes and powder types, making it versatile for different pharmaceutical products.

- Regulatory Compliance: The line is built to meet global pharmaceutical regulatory standards, ensuring that the final products are safe, reliable, and ready for market distribution.

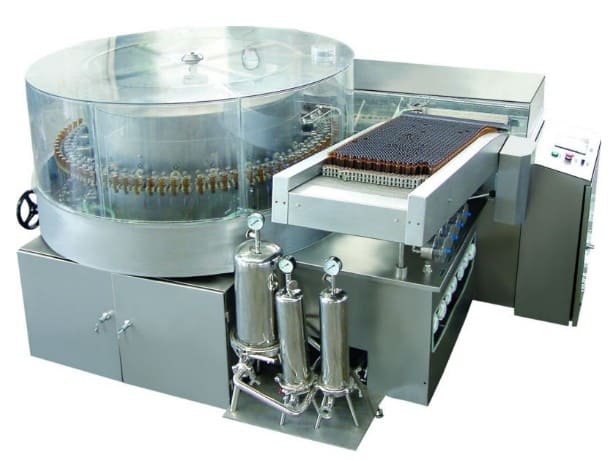

Vial Washing Machine

Introducing KTS Pharmatech cutting-edge Vial washing machine, designed to meet the stringent cleanliness standards of pharmaceutical and biotech industries. This state-of-the-art equipment ensures thorough and efficient cleaning of Vials, removing any contaminants or impurities. With a user-friendly interface and automated processes, our machine is capable of handling high volumes while maintaining consistent quality. Its advanced technology guarantees reliable sterilization, making it an essential tool for enhancing the safety and integrity of pharmaceutical products. Trust in our ampoule washing machine to streamline your operations and uphold the highest hygiene standards in your production facility.

Sterilization and Depyrogenation Tunnel

Introducing KTS Pharmatech sterilization and depyrogenation tunnel, designed to meet the stringent requirements of pharmaceutical and biotech industries. This advanced equipment ensures thorough sterilization and depyrogenation of vials, Ampoules, and other pharmaceutical containers. With a user-friendly interface and automated processes, our tunnel is capable of handling high volumes while maintaining consistent quality. Its advanced technology guarantees reliable removal of pyrogens and contaminants, making it an essential tool for enhancing the safety and integrity of pharmaceutical products. Trust in our sterilization and depyrogenation tunnel to streamline your operations with uncompromising hygiene standards in your production facility.

Vial Powder Filling and Rubber Stoppering Machine

KTS Pharmatech’s Vial Powder Filling Machine delivers precise and efficient powder filling for the pharmaceutical industry. Designed for accuracy and versatility, it handles various vial sizes and powder types with ease. The machine features automated controls and a user-friendly interface, ensuring streamlined operation and minimal manual intervention. Adhering to strict industry standards, it ensures safe and reliable filling, making it an essential asset for high-quality pharmaceutical production.

Vial Cap Sealing Machine

KTS Pharmatech’s Vial Cap Sealing Machine is designed to provide secure and efficient sealing for vials. It ensures tamper-evident closures, maintaining product safety and integrity. The machine features advanced sealing technology for precise and reliable performance, handling various vial sizes and cap types with ease. With its user-friendly interface and high-speed capabilities, it is an essential tool for pharmaceutical and healthcare industries, ensuring consistent, and high-quality seals while optimizing production efficiency.

External Vial Washing Machine

KTS Pharmatech’s vial washing machine is comprehensively made for the purpose of washing of the outer surface of the circle shaped vials. It is specifically incorporated for the washing the outer sides of vials and thereby diminishes the particles that are formed on the vials.

Visual Inspection Machine

KTS Pharmatech’s vial visual inspection machine is appropriate for inspection of dry powder vials inside the injectable. Also made to use for inspection of vial for any kind of breakage. Equipped with long lasting and maintenance free rollers. Works perfectly in compliance to the cGMP standards

Vial Labelling Machine

KTS Pharmatech provides a Vial labelling machine is designed to efficiently and accurately apply labels to ampoules, small sealed vials commonly used in the pharmaceutical industry. These machines operate at high speeds to handle large production volumes, ensuring precise and consistent label placement. They are versatile, accommodating various Vial sizes and label types, and feature user-friendly controls for easy operation. Vial labelling machines are essential for maintaining compliance and traceability in pharmaceutical manufacturing.

Packing Conveyor

KTS Provide Packing conveyor that is use at the end of Process line where packaging of final product is performed by manpower. During this process operators picks up the products and does necessary action like Primary Packing and Secondary Packing.

Box Tape Sealing Machine

KTS Pharmatech’s Box Tape Sealing Machine automates the process of sealing boxes with tape, providing a fast and reliable solution for packaging. Designed for precision and consistency, it handles various box sizes and tape widths with ease, ensuring strong, secure seals. This machine enhances operational efficiency and reduces manual labor, making it a vital addition to any packaging line.