Milk / Butter Milk Packing Line

The Milk/Buttermilk Packing Line by KTS Pharmatech is a comprehensive, high-efficiency system designed for the precise and reliable packaging of milk and buttermilk. This line integrates advanced automation to handle the entire packaging process, from filling to sealing and labelling.

The Milk/Buttermilk Packing Line by KTS Pharmatech is engineered to boost productivity, ensure hygiene, and maintain high-quality standards in the packaging of liquid dairy products.

Key Features:

- Automated Filling: Ensures accurate and consistent filling of milk and buttermilk into various container types and sizes, optimizing product volume and reducing waste.

- Capping Technology: Provides secure and leak proof seals to preserve freshness and extend shelf life.

- Labelling System: Applies labels with high precision, ensuring clear product information and compliance with industry standards.

- High-Speed Operation: Enhances production efficiency, allowing for high-volume processing with minimal manual intervention.

- Quality Control: Includes features for monitoring fill levels, seal integrity, and label accuracy to ensure consistent product quality.

Applications:

- Dairy Industry: Perfect for packaging a range of milk and buttermilk products, meeting the demands of both retail and bulk distribution.

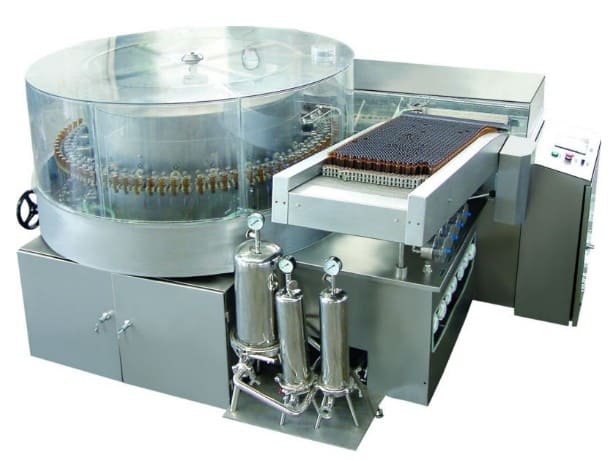

Semi-Automatic Rotary Bottle washing machine

The semi-automatic rotary bottle washing machine from KTS Pharmatech is designed for efficient and thorough cleaning of bottles in a rotary motion. This machine features a rotating mechanism that ensures comprehensive wash coverage, removing contaminants and residues effectively. With its semi-automatic operation, it combines ease of use with high cleaning standards, making it ideal for pharmaceutical, food, and beverage industries. The machine enhances productivity while maintaining rigorous hygiene and sanitation standards.

Capping machine

KTS Pharmatech’s Screw and ROPP (Roll-On Pilfer Proof) Capping Machines are engineered to provide reliable and efficient closure solutions for a wide range of packaging needs.

- Screw Capping Machines: Designed for precision and versatility, these machines apply screw caps to bottles with consistent torque and secure closure. Ideal for various industries, including pharmaceuticals, food, and beverages, they ensure tamper-evident and leak-proof seals.

- ROPP Capping Machines: Utilize a roll-on technique to apply aluminum caps, creating a tamper-evident seal that protects product integrity. Perfect for applications where security and authenticity are crucial, such as in the pharmaceutical and cosmetic industries.

Both types of capping machines are built to enhance productivity, reduce manual handling, and maintain high-quality standards. With advanced technology and user-friendly controls, KTS Pharmatech’s capping solutions ensure reliable performance and compliance with industry

Bottle labelling machine

KTS Pharmatech provides a Vial labelling machine is designed to efficiently and accurately apply labels to ampoules, small sealed vials commonly used in the pharmaceutical industry. These machines operate at high speeds to handle large production volumes, ensuring precise and consistent label placement. They are versatile, accommodating various Vial sizes and label types, and feature user-friendly controls for easy operation. Vial labelling machines are essential for maintaining compliance and traceability in pharmaceutical manufacturing.