Oral Liquid Packing Line

At KTS Pharmatech, we specialize in designing and manufacturing cutting-edge oral liquid packing lines tailored for the pharmaceutical industry. Our advanced systems integrate precision filling, reliable capping, efficient labelling, and robust quality inspection to ensure high performance and regulatory compliance. Committed to innovation and excellence, KTS Pharmatech delivers comprehensive packaging solutions that enhance productivity, maintain product integrity, and meet the evolving needs of the market. Discover how our expertise can streamline your liquid packaging processes and drive your success.

When designing or evaluating an oral liquid packing line, several key components are essential for ensuring efficiency, accuracy, and compliance with industry standards. Here’s a breakdown of these critical elements.

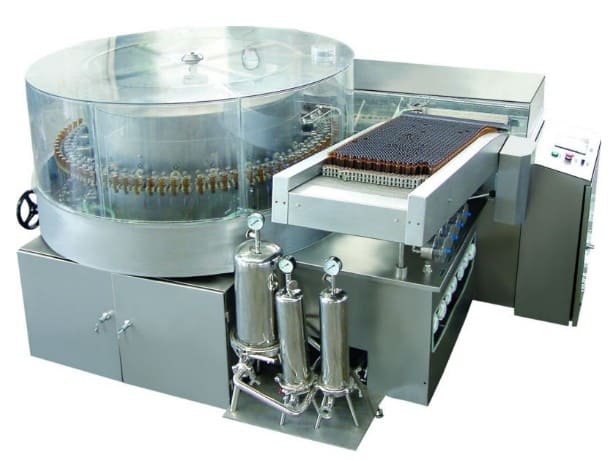

Semi-Automatic Rotary Bottle Washing Machine

The semi-automatic rotary bottle washing machine from KTS Pharmatech is designed for efficient and thorough cleaning of bottles in a rotary motion. This machine features a rotating mechanism that ensures comprehensive wash coverage, removing contaminants and residues effectively. With its semi-automatic operation, it combines ease of use with high cleaning standards, making it ideal for pharmaceutical, food, and beverage industries. The machine enhances productivity while maintaining rigorous hygiene and sanitation standards.

Liquid Filling Machine

KTS Pharmatech offers a range of oral liquid filling machines tailored to meet diverse production needs:

- Volumetric Fillers: Provide precise liquid measurement with piston or peristaltic mechanisms, suitable for varying viscosities.

- Gravity Fillers: Utilize gravity for efficient filling of low-viscosity liquids.

- Pump Fillers: Feature gear or diaphragm pumps for accurate filling of both thin and thick liquids.

- Overflow Fillers: Ensure uniform fill levels by managing excess liquid.

- Automatic Systems: Integrate with capping and labeling for high-speed, automated filling processes.

- Multi-Head Fillers: Increase efficiency and throughput with multiple filling heads for large-scale production.

These categories ensure KTS Pharmatech can offer solutions that enhance precision, efficiency, and reliability in oral liquid production.

Capping Machine

KTS Pharmatech’s Screw and ROPP (Roll-On Pilfer Proof) Capping Machines are engineered to provide reliable and efficient closure solutions for a wide range of packaging needs.

- Screw Capping Machines: Designed for precision and versatility, these machines apply screw caps to bottles with consistent torque and secure closure. Ideal for various industries, including pharmaceuticals, food, and beverages, they ensure tamper-evident and leak-proof seals.

- ROPP Capping Machines: Utilize a roll-on technique to apply aluminum caps, creating a tamper-evident seal that protects product integrity. Perfect for applications where security and authenticity are crucial, such as in the pharmaceutical and cosmetic industries.

Both types of capping machines are built to enhance productivity, reduce manual handling, and maintain high-quality standards. With advanced technology and user-friendly controls, KTS Pharmatech’s capping solutions ensure reliable performance and compliance with industry regulations.

Visual Inspection Conveyor

KTS Pharmatech introduces the Visual Inspection Conveyor, a cutting-edge solution designed to enhance quality control in manufacturing. This advanced conveyor system provides real-time, automated/semi-automated inspection of products, ensuring the detection of defects and inconsistencies with precision. Featuring Black and white inspection film with Lights and Magnifying glass, adjustable settings, and seamless integration into existing production lines, it offers efficient, reliable performance to maintain high-quality standards and regulatory compliance.

Measuring Cup Placement Machine

KTS Pharmatech’s Measuring Cup Placing Machine automates the precise and efficient placement of measuring cups onto containers/Bottles. This advanced system enhances production speed, reduces manual labor, and ensures consistent positioning, seamlessly integrating into existing production lines for improved operational efficiency.

Bottle Labelling Machine

KTS Pharmatech provides a Vial labelling machine is designed to efficiently and accurately apply labels to ampoules, small sealed vials commonly used in the pharmaceutical industry. These machines operate at high speeds to handle large production volumes, ensuring precise and consistent label placement. They are versatile, accommodating various Vial sizes and label types, and feature user-friendly controls for easy operation. Vial labelling machines are essential for maintaining compliance and traceability in pharmaceutical manufacturing.

Packing Conveyor

KTS Provide Packing conveyor that is use at the end of Process line where packaging of final product is performed by manpower. During this process operators picks up the products and does necessary action like Primary Packing and Secondary Packing.

Box Tape Sealing Machine

KTS Pharmatech’s Box Tape Sealing Machine automates the process of sealing boxes with tape, providing a fast and reliable solution for packaging. Designed for precision and consistency, it handles various box sizes and tape widths with ease, ensuring strong, secure seals. This machine enhances operational efficiency and reduces manual labor, making it a vital addition to any packaging line.