Automatic Nested Pre-Filled Syringe Filling Machine

KTS Pharmatech’s Automatic Pre-Filled Syringe Filling Machine is a cutting-edge solution designed for the precise and efficient filling of syringes with liquid medications. This fully automated system ensures accurate dosing and high-speed production while maintaining rigorous hygiene standards. Engineered for versatility, it accommodates various syringe sizes and liquid viscosities, enhancing operational efficiency and compliance with pharmaceutical regulations. KTS Pharmatech’s machine delivers reliable performance and consistent quality, making it ideal for the pharmaceutical and biotech industries.

Salient Features

- Machine is designed and manufactured in accordance with cGMP compliance.

- Structure is made of SS 304.

- Machine suitable for different syringe size with help of change part and depends on characteristic of liquid.

- Pre filled syringe in Nest form can be filled with this machine.

- Conveyor for Tub transfer.

- Manually De bagging of empty nested pre filled syringe Tub.

- Manual Tyvek removal and Lid removal.

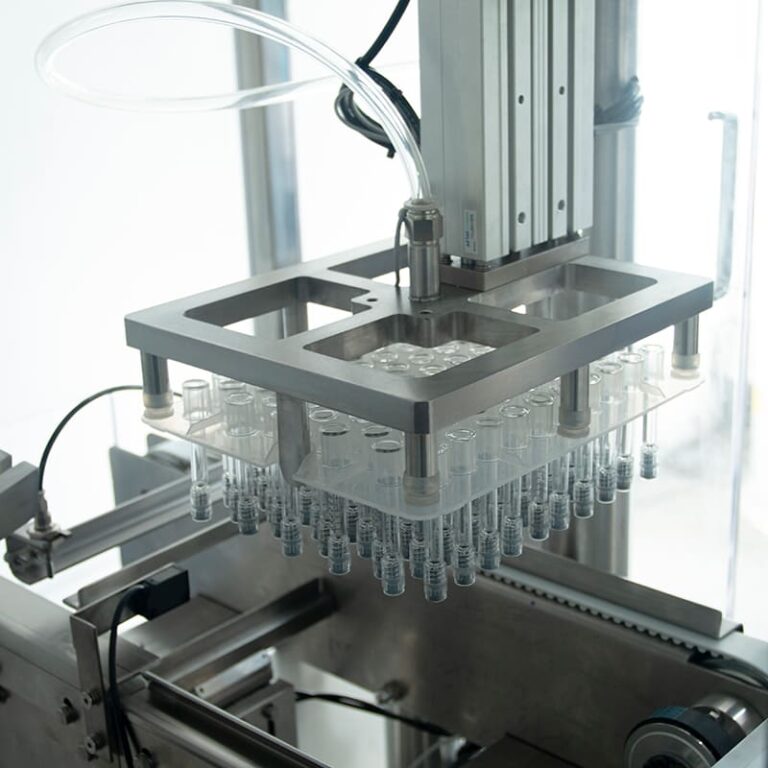

- Automatic empty Nest transfer system for filling operation.

- Gantry system for movement of Nest for filling and stoppering.

- Servo controlled Dive in nozzle system for filling operation.

- Filling with Metal Syringe or Peristaltic pump.

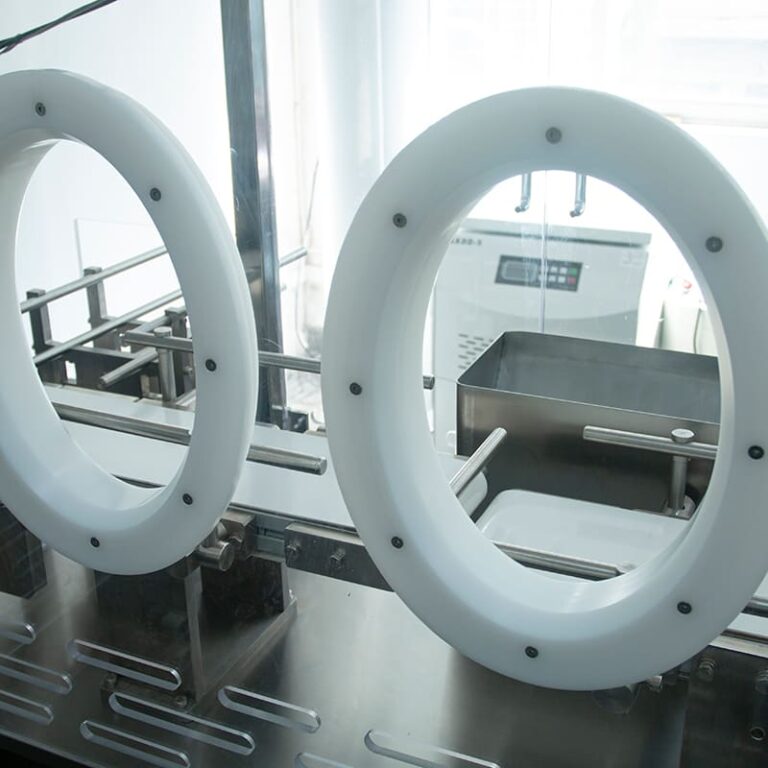

- Vacuum or PIPO rubber stoppering system.

- Rotary and Linear vibratory system for rubber transfer.

- Filling volume to be controlled by PLC controlled HMI.

- Most reliable components of pneumatics and electrical/electronic such as AC motor, AC Drive, PLC & HMI, Sensor, MCB & relay “CE” make.

Special Features

- Low Air machine stop sensor.

- Door interlocking system.

- Suitable PLC with programming & 7”/10” colour touch screen HMI.

- FDA/USFDA approved grade silicon tube for filling, CIP/SIP.

- Minimum changeover time and parts.

- Machine can provide with LAF as per required class (Optional).

- Diving of Nozzle can be controlled by means of HMI only.

- Product counter with password protection that will provide daily track report.

- Any alarm will be display on HMI screen.

- User friendly and very less maintenance.

- Nitrogen Flushing System (Optional).

Technical Specifications

| Model | FILLKTS-A-NPFS |

|---|---|

| Model Type | Servo |

| Product Type | Nested Pre filled syringe |

| Output (Product/hour) max. | 4800 (Depends on fill volume and product Size) |

| Power consumption (hp) | 5 |

| Power supply | Three Phase, 440 Volts, 50 Hz |

*Rights of technical improvements & modification reserved.

Are You Interested in KTS Pharmatech Machine?